What Are The Benefits of 3D Printing in Space?

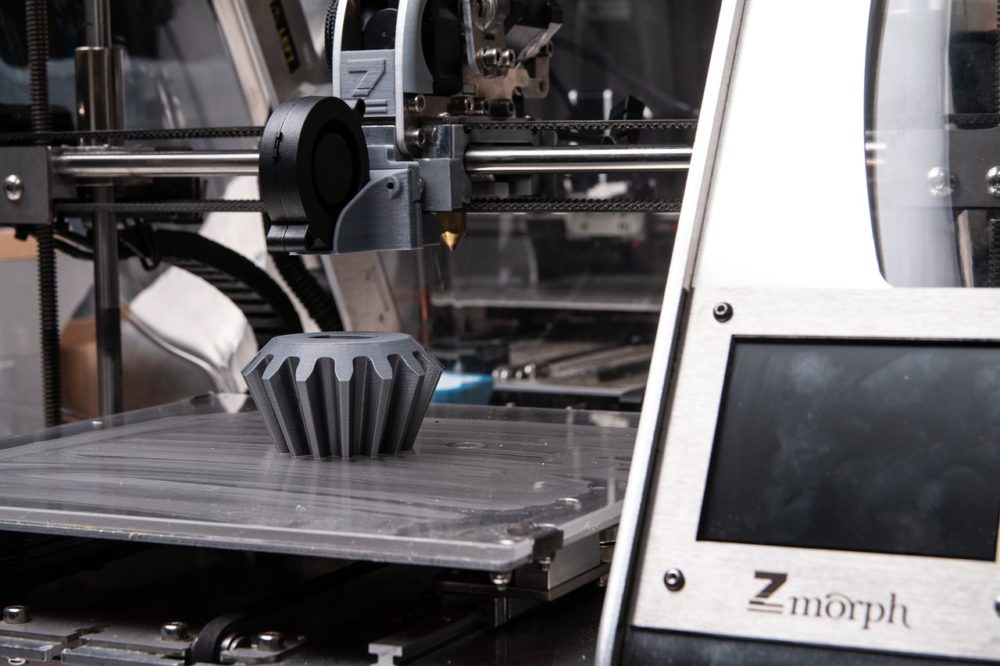

3D printing has moved from a hobbyist’s best friend to one of the most useful tools in nearly every industry. With a computer and a bit of heat, you can turn strings of plastic filament into nearly anything. More advanced types of 3D printers can even lay down layers of metal, glass, or cement. There is even a 3D printer in orbit above the Earth on the International Space Station. What are the benefits of 3D printing in space and will we see more of it in the future?

Keeping Rocket Weight Low

That same gravity that keeps you from floating away from the Earth’s surface also makes it difficult for us to get into outer space. You need to move at more than 40,000 kilometers per hour to reach what’s known as escape velocity and break free of the Earth’s gravitational pull. The more your rocket weighs, the more difficult it is to reach escape velocity, so aerospace engineers are always looking for new ways to reduce the amount of weight we’re launching into orbit.

3D printing gives astronauts everything they need to make a massive variety of different items, all without needing to ship each piece into orbit. If they need a bowl, they can print a bowl, and all NASA has to do is send up a couple of rolls of 3D printing filament.

Forgot Your Tools?

If you forget your tools at home, you can usually just drive back and pick them up. What do you do if you’re an astronaut and home is 254 miles below your feet? You print a new one! Astronauts on the International Space Station have worked with engineers and designers on the ground to print specialized tools that they didn’t bring with them. In 2014, astronauts printed a wrench that they needed to carry out a repair.

Unlike printing here on Earth, the wrench needed to have moving parts but had to be completely enclosed to prevent the small pieces from floating away in the station’s microgravity. It took four hours to print and when it was done, the astronauts could finish the job they’d started.

Building Spacecraft

We’ve been building spacecraft for decades, and as we’ve learned we’ve changed our manufacturing techniques. What started with hand-crafted pieces changed to assembly lines and robotic manufacturing. 3D printing isn’t a new concept either though when it debuted in 1986 it didn’t look much like the technology we know today. Soon, we may even see starships made of fully 3D printed parts, especially if we start designing them with pieces that are too complex to fabricate traditionally.

If we start building massive ships in space that aren’t designed for atmospheric flight, like many of those that we see in science fiction movies and stories, microgravity 3D printing could make a massive difference — it’s a lot easier to send a robotic printer out into the vacuum of space than it is to send a human astronaut in a spacesuit.

Recycling in Space

One problem with sending humanity into outer space is that we tend to generate trash wherever we go. The International Space Station is no exception. 3D printing gives astronauts a way to turn their plastic waste into something useful by recycling it into 3D printing filament. There are currently two 3D printers on the International Space Station — the Refabricator and an Additive Manufacturing Facility (AMF). Another device, known as The Recycler, works by turning plastic waste into 3D filament that they can feed back into the Refabricator.

This means that there is less waste that needs to be discarded or returned to Earth, keeping things cleaner for everyone.

Printing…Meat?

Keeping astronauts fed and healthy can be challenging, especially during the kind of long-distance journeys we hope to undertake in the future. In Star Trek, they solved that problem with the invention of replicators — devices that could materialize nearly any food or drink you could imagine with nothing more than a voice command. While we haven’t quite figured out how to replicate food, 3D printing might make it a little bit easier.

In the future, 3D printers may be able to print anything from food to medicine and anything in between, using a limited store of base materials. While a 3D printed steak might not sound appetizing when you can just drive to the grocery store and buy one, if you’re a few million miles from the nearest cow, it might be the tastiest meal you could cook up.

In-Flight Repairs

The last thing you want to contend with in outer space is a breach in your hull. Exterior damage is tricky to fix, even on Earth, and you don’t want to spend astronauts out unless you absolutely have to. Why not use a 3D printer on the end of a robotic arm to affect repairs if something goes wrong or punches through your hull?

The deep-space ship Aether featured in the recent Netflix movie The Midnight Sky showcased this potential application for the technology. After the ship flies through an ice storm, the crew is able to send bots out along rails affixed to the exterior of the craft to fix the damage. It’s a unique look at 3D printing technology that may see more practical applications in the future.

Looking Toward the Future

We’re not quite up to exploring the galaxy — at least not yet. When we move beyond the Moon and Mars and eventually our home solar system, 3D printing and it’s technological descendents will be there to help us build all the pieces we need to reach our destination safely.

Would you like to receive similar articles by email?